About Our Injection Molding Facility

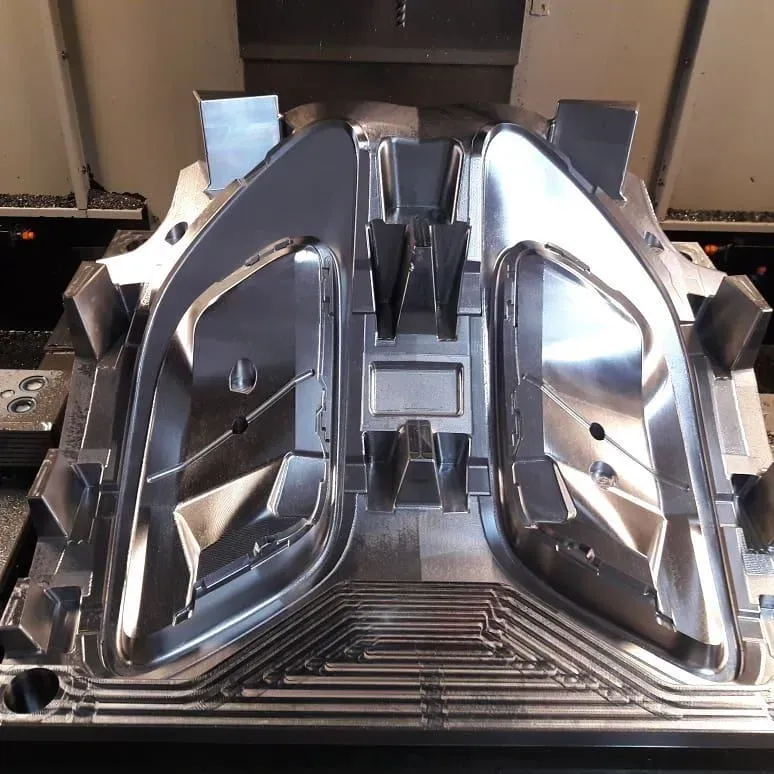

Our quality services start at our facility. Bullmold has a world-class facility with over 3300 square feet of production and warehouse space, making us one of the largest injection molding manufacturers in Guangdong. We have 18 injection molding machines ranging from 80 to 850 tons that utilize the most advanced technologies, including robotics, gas-assist, and water-assist technologies. Our facility also has almost 1500 tons of clamping force under one roof. No matter what your needs are, our large-scale, diversified array of options means that we’re ready to take on your next project, no matter how big or small.

Why Choose Our Injection Mold Company?

Bullmould has over 20 years of experience in quality injection molding. We believe our standards are what set us apart. Everyone has their own unique needs, and our mission has always been to meet each one with a perfect custom approach. We take the time to carefully listen to every client, making sure we understand the unique needs and goals of every partnership before we start. This priority placed on high-quality results coupled with the ease of working with us causes our clients to become customers for life.

Why Our Facility Stands Out?

We owe a lot to our outstanding facility for keeping us a leader in the injection molding industry. With our close location to HK, We can send products from Hong Kong to customers in various countries with low transportation costs, Bullmould’s Lean Chinese Manufacturing Achieves Lowest Landing Costs, This is how we have provided many Fortune 500 customers with lower landed costs than even others.

Dedicated Quality Assurance.

Bullmould is committed to total customer satisfaction. It is our objective to create long-lasting relationships with our clients by manufacturing quality injection molding products that meet customer requirements, are competitively priced, and are delivered on time. We achieve these objectives through the establishment, maintenance, and continual improvement of our ISO 9001:2015 certified, ISO/TS 16949-compliant quality management system. We employ a staff of over 60 employees, and our facility operates 24/7/365 to ensure you receive your injection molding orders on time. Bullmold makes sure every product we produce is one we’d be happy to put our name on.

The Bullmould Process

Here at Bullmould, we’ve worked hard to fine-tune our process in order to cut down on lead times and ensure the on-time arrival of orders. you can focus on ensuring that the quality of your product, part, tool, component, etc. meets your standards.

QUOTE PHASE

Step1: Quote Phase

After you get in touch with us, one of our team members will ask you for more information about your inquiry, including CAD files, production qtys, materials, drawings, etc.

If you acquire design assistance, we have people that can help. Our designer extensive plastic design experience coupled with our excellent knowledge in injection molding allows us to put your dream together and bring your ideas into reality.

If you require new tooling, Bullmould will provide you with a budgetary quote.

If you’re comfortable with the budgetary pricing, after accepting and sending off your PO, we’ll then send you a customer credit profile to set you up in our system.

If new tooling is required we’ll also send the invoice for the tooling deposit at this time.

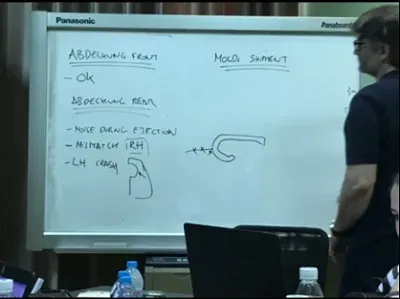

Step2: Mold Design & Creation

Next, we’ll ask you to provide us with the final CAD designs and pay for the mold deposit. Once that’s settled, we’ll complete a DFM and send it to you so that you can review the design and ensure it’s ready for production according to your specifications.

If the DFM is approved and there are no changes to the design, the mold design is then created.

After mold design creation, we will sit down with you to review the design. Once you’ve approved the mold design, the mold build begins and can last anywhere from 8-12 weeks.

After being built, Our project engineer will take T0 shots to make sure the mold functions properly.

If there are no problems, we will manufacture T1 samples from the correct material and molding process for the purpose of sending parts and a report to you to approve the mold.

If there are no changes needed, the mold can be prepared for shipment. If it is to continue to manufacture products in our company, we complete an inspection of the mold before hanging the mold in a machine and completing our own first article production run to complete the final approval of the mold and parts.

Step3: Production

Once you’ve approved the mold for production, you’ll place a PO for however many parts you want. We’ll then order all the materials needed for the production run. Once all the materials have arrived we will run the production order.

Finished products are then moved into our warehouse, where we focus on the logistics of getting your finished products to where they need to go.

Step4: Logistics & Delivery

No matter how you take your products, be it a truckload at a time or via several smaller shipments, we’ll work with you to ensure their safe and speedy delivery. We can even help you use a Kanban card system, where we go into a portal and look to see if you need us to ship to you. If you send us your customer specifics, we can also ship directly to your customers’ parcels by preparing, labeling, and shipping the products out.

Step5: Get A Quote

Have questions about our process? Curious to see what’d it’d cost for us to manufacture the products, parts, or components you need? We’d love to hear from you! Just fill out the form below and our team will be back in touch within 24 hours.